Top quality throughout the entire product life cycle:

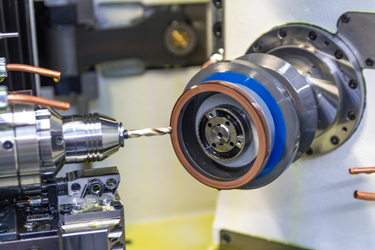

With our high-quality regrinding and recoating service, we ensure that your tool is reconditioned to the quality you would expect from the manufacturer at the end of its service life – and in a very short time too.

You can then use it in your manufacturing operation once more with its original geometry and original coating and obtain the usual results.

We have fundamentally overhauled the reconditioning of solid carbide drills: with a separate department, modern IT and separate machinery. In this way, we achieve short processing times and offer maximum reconditioning quality. An attractive logistics concept ensures smooth, swift processing.

The benefits at a glance:

- Regrinding to the original MILLER quality – significant reduction in unit costs as a result

- Short processing times and completion on schedule – smooth production process

- Attractive logistics concept – concentration on core competencies

Reliable transport

Upon request, we provide a MILLER toolbox for transportation. Please contact us for further details.